Flame Spray Coating

Flame Spray Coating Specification

- Max Operating Temperature

- up to 1100C

- Colour

- Metallic Grey or Customizable

- Shelf Life

- 12 Months for consumables

- Density of Coating

- Varies by material, approx. 68 g/cm

- Bond Strength

- Typically 3570 MPa

- Service Life

- 510 Years (typical, depends on environment)

- Substrate Compatibility

- Steel, Stainless Steel, Cast Iron, Aluminum

Flame Spray Coating Trade Information

- Minimum Order Quantity

- 1 Square Meter

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Western Europe, Middle East, Central America, Africa, South America, Australia, Asia, Eastern Europe, North America

- Main Domestic Market

- All India

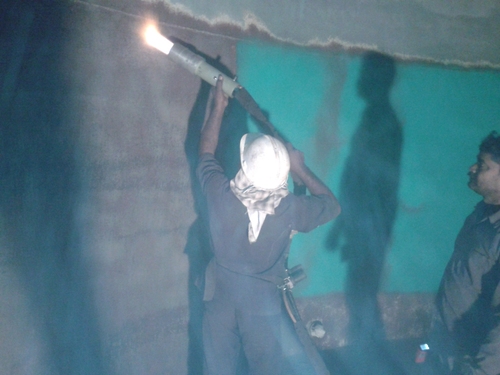

About Flame Spray Coating

As a prominent enterprise, we are engaged in offering Flame Spray Coating services to our clients at competitive prices. We have a diligent team of professionals possessing immense experience in this domain thereby, enabling us to render offered services in the most effective manner. Under the most favorable conditions, the requisite equipment is coated with flame spray with utmost care and high precision. The rendered services make the coated equipment, impact and corrosion resistance. Widely demanded in agriculture and oil exploration industry, these Flame Spray Coating services are known for reliability, timeliness and flexibility.

Specifications:

- No VOC - Environment Friendly

- High Coating Thickness Per Single Coat. (Up To 300 Microns)

- In-Situ Application Possible

- Wide Range of Thermoplastic Compositions to suit varied Applications

- FDA Approved Products For Portable Water Storage Tanks

FAQs:

Q: What is flame spray coating?

A: Flame spray coating is a thermal spray process in which a material is melted and atomized by a flame and then deposited onto a substrate to form a coating.

Q: What materials can be used for flame spray coating?

A: A wide range of materials can be used for flame spray coating, including metals (such as aluminum, zinc, and nickel), ceramics, and polymers.

Q: What are the benefits of flame spray coating?

A: The benefits of flame spray coating include improved wear resistance, corrosion protection, and increased surface hardness. Flame spray coating can also be used to repair damaged surfaces or to improve the performance of new components.

Q: What are the types of flame spray coating?

A: The two main types of flame spray coating are metal spray and ceramic spray. Metal spray is used for the application of metallic coatings, while ceramic spray is used for the application of ceramic or polymeric coatings.

Q: What are the disadvantages of flame spray coating?

A: The potential disadvantages of flame spray coating include the generation of heat and the potential for thermal damage to the substrate, as well as the need for specialized equipment and trained personnel. Additionally, the surface finish of the coating can be somewhat rough, which may require additional processing or finishing.

Exceptional High Temperature Protection

Engineered to endure elevated operating conditions, our Flame Spray Coatings provide reliable protection for components subject to heat, withstanding temperatures up to 1100C. This ensures integrity and safety in extreme industrial environments, minimizing downtime and maintenance costs.

Versatile Compatibility with Metals

Our coating solutions adhere effectively to steel, stainless steel, cast iron, and aluminum, delivering strong bonds and maintaining consistent density of around 68 g/cm. This versatility allows for broad application across multiple industries, including automotive, petrochemical, and manufacturing.

Customizable Appearance and Performance

Flame Spray Coating is available in standard metallic grey or can be tailored to match specific aesthetic requirements. The process ensures reliable bond strength and a service life of up to 10 years, with consumables maintaining performance for 12 months when stored properly.

FAQs of Flame Spray Coating:

Q: How does Flame Spray Coating protect metal substrates at high temperatures?

A: Flame Spray Coating provides a robust protective layer that withstands operating temperatures up to 1100C, preventing oxidation, corrosion, and thermal fatigue in steel, stainless steel, cast iron, and aluminum substrates.Q: What is the typical process for applying Flame Spray Coating?

A: The coating is applied using a specialized thermal spray torch, which melts and propels the coating material onto the prepared substrate, forming a dense, adhered layer with bond strength between 3570 MPa.Q: When should Flame Spray Coating consumables be replaced?

A: Consumables used in the flame spray process have a shelf life of 12 months. For optimal performance, they should be replaced before expiration, ensuring consistent quality and coating integrity.Q: Where can Flame Spray Coating be used most effectively?

A: This coating is ideal for environments requiring durable protection against heat and corrosion, such as furnace components, engine parts, petrochemical equipment, and industrial machinery operating in India and globally.Q: What are the main benefits of using Flame Spray Coating?

A: Using Flame Spray Coating enhances component durability, extends service life (typically 510 years), improves resistance to wear, and offers customizable appearance while maintaining high bond strength and density.Q: Is the color of Flame Spray Coating customizable?

A: Yes, while the standard finish is metallic grey, the coating can be customized to meet specific color requirements, depending on user preferences and project specifications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry