Thermoplastic Rubber Coatings

Thermoplastic Rubber Coatings Specification

- Solvent Resistance

- Excellent

- Surface Preparation Required

- Yes, Clean and Dry Surface

- Adhesion to Substrates

- Metal, Plastic, Rubber, Concrete

- Flexibility

- High

- Shelf Life

- 12 months

- Finish

- Smooth and Even

- Storage Condition

- Cool and Dry Place

Thermoplastic Rubber Coatings Trade Information

- Minimum Order Quantity

- 100 Square Meters

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Square Meters Per Day

- Delivery Time

- 1 Week

- Main Export Market(s)

- Asia, Australia, North America, Eastern Europe, Middle East, Central America, Africa, South America, Western Europe

- Main Domestic Market

- Dadra and Nagar Haveli, Himachal Pradesh, Andaman and Nicobar Islands, Pondicherry, Uttarakhand, Daman and Diu, Lakshadweep, Delhi, Gujarat, Karnataka, Chandigarh, Tripura, Haryana, Assam, Rajasthan, Arunachal Pradesh, , Manipur, Punjab, Jammu and Kashmir, Sikkim, Telangana, Maharashtra, Meghalaya, Mizoram, North India, Goa, Madhya Pradesh, Bihar, Tamil Nadu, West Bengal, East India, South India, Nagaland, Kerala, Andhra Pradesh, Central India, Odisha, Jharkhand, West India, Chhattisgarh, Uttar Pradesh, All India

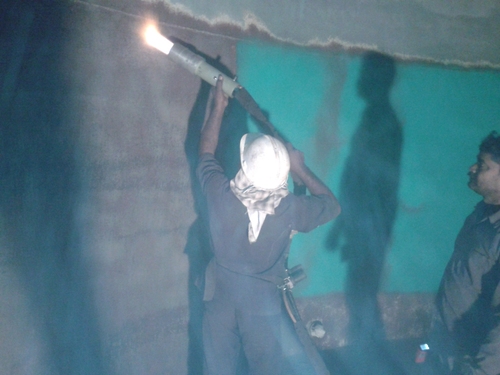

About Thermoplastic Rubber Coatings

By keeping pace of latest market developments, we draw pride in offering highly reliable Thermoplastic Rubber Coatings service to our esteemed clients. In order to achieve the satisfaction of our clients, our adept professionals closely interact with the clients to comprehend their exact needs. With the aid of latest machinery & tools, we render this service by precisely coating the entire surface of requisite materials with the thermoplastic rubber. Furthermore, we ensure chemical & corrosion resistance of the coated material. These Thermoplastic Rubber Coatings service is appreciated for promptness, cost-effectiveness, professionalism and flexibility.

Specifications:

- Low Water Absorption

- Low Friction

- High Chemical Reistance

- Non-Stick Properties

- Easy To Clean.

Advanced Protection and Versatility

Thermoplastic Rubber Coatings provide reliable protection for diverse surfaces such as metal, plastic, rubber, and concrete. These coatings are ideal for projects requiring flexibility and solvent resistance, guaranteeing longevity and performance. With simple surface preparation, users can achieve a highly smooth result, making them suitable for various environments and industries across India.

Optimized Storage and Shelf Life

To maximize the effectiveness of the coating, it should be stored in cool, dry conditions. The product retains its quality for up to 12 months, offering a practical solution for both ongoing and future projects. Such conditions help preserve the coatings properties, ensuring consistent adhesion and durability when applied.

FAQs of Thermoplastic Rubber Coatings:

Q: How should the surface be prepared before applying Thermoplastic Rubber Coatings?

A: Surfaces must be thoroughly cleaned and dried before application to ensure optimal adhesion and a smooth, even finish. Proper surface preparation removes dust, grease, and contaminants for best performance.Q: What are the benefits of using Thermoplastic Rubber Coatings on metal, plastic, rubber, and concrete substrates?

A: These coatings deliver high flexibility, excellent solvent resistance, and strong adhesion, making them ideal for protecting and finishing varied substrates against wear, chemical attack, and environmental exposure.Q: When is it best to use Thermoplastic Rubber Coatings after purchase?

A: The coatings should be used within their 12-month shelf life, which is maintained by storing the product in a cool, dry place to preserve its quality and effectiveness.Q: Where can Thermoplastic Rubber Coatings be effectively applied?

A: They are suitable for industrial, commercial, and construction projects across India, particularly on metal, plastic, rubber, and concrete surfaces that require durable and solvent-resistant finishes.Q: What is the application process for these coatings?

A: Begin by preparing the substrateensuring it is clean and drythen evenly apply the coating using appropriate tools. Allow sufficient drying time as recommended for the best finish and durability.Q: How does excellent solvent resistance benefit the end user?

A: High solvent resistance prevents damage from chemicals and exposure, prolonging the lifespan of coated surfaces. This enhances protection in environments where chemical spills or aggressive cleaning agents are common.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry